The Daily Decision That Determines Everything

Every morning at Alimentos Prosalud, one of the main seafood processors in the western hemisphere, production planners make a critical decision that determines the next four days of work: How much tuna should leave cold storage and enter the plant today?

That single release decision commits the factory to a chain of dependent processes: cleaning, cutting, canning, sterilization, and labeling. Once tuna leaves the frigorífico, there is no rewind button. Too much release creates congestion and excess work-in-process. Too little release starves bottlenecks and leaves people waiting.

"For years, planners made this decision the only way they realistically could: by stitching together thousands of lines of Excel. Inventory lived in one file. Restrictions lived in another. SKU rules, species compatibility, and operational constraints lived mostly in people's heads."

Producing a feasible plan routinely consumed most of a working day. The problem was not a lack of expertise—it was the friction created by fragmented information and irreversible decisions.

Aerial view of Alimentos Prosalud's facilities in Costa Rica

Turning Judgment into Something You Can Work With

ProDex provided our Advanced Planning and Scheduling module to formalize how Alimentos Prosalud's planners made decisions without replacing their judgment or forcing a "black-box" tool into the process.

The platform centralizes cold-storage inventory, release quantities, and operational rules into a single planning surface. Instead of reconciling 18 spreadsheets, planners have a clear decision-making workflow to make three core decisions:

- What enters the plant

- In what quantity

- On which day

The system enforces SKU and raw material constraints automatically and flags violations before they propagate downstream.

"The system alerts us before making an incorrect assignment—SKU, species, or restriction."

— Alimentos Prosalud Planning Team

A look inside the tuna cutting process at Alimentos Prosalud

From a Day of Work to Minutes

The most visible impact showed up immediately in planning time.

The time savings did not come from cutting corners. It came from removing manual reconciliation and codifying tribal knowledge, which accelerated decision-making.

"The distribution of tuna for cleaning is faster and more precise."

— Alimentos Prosalud Planning Team

That speed mattered because it changed how planners spent their attention. Instead of assembling plans, they now focused on evaluating intricate tradeoffs. Rapid replanning was once a nice-to-have. With the speed and visibility unlocked by ProDex, iterative planning and improved precision became the norm.

Designing a Natural Interface

One reason adoption happened quickly and easily was the interface design. It matched how planners already worked. The system did not introduce new abstractions or dashboards. It gave planners a visual surface where assignments could be adjusted directly.

"The interface makes it easy to visualize and adjust assignments."

Drag-and-drop scheduling replaced copy-paste logic. Small changes no longer required rebuilding the entire plan. Planning became lighter and more fluid while preserving complexity.

Just as important was how the system evolved. Planner feedback translated into product changes almost immediately.

"The team understood what we needed very quickly and adapted the tool to how we actually work."

"Updates and fixes came in one to two days."

Saving Complex Business Logic as Rules

The single most important effect of our software is that we've stopped costly errors by codifying very complex business logic in production planning decisions. A simple misclick in an Excel sheet is no longer a point of failure for the entire production planning process.

The ProDex agent operates like an Operations Research engineer and joins our production planners in their daily workflow. The agent learns from each day of planning, and, for complex edge cases, allows the user to add rules via simple conversations which it remembers and applies in the future.

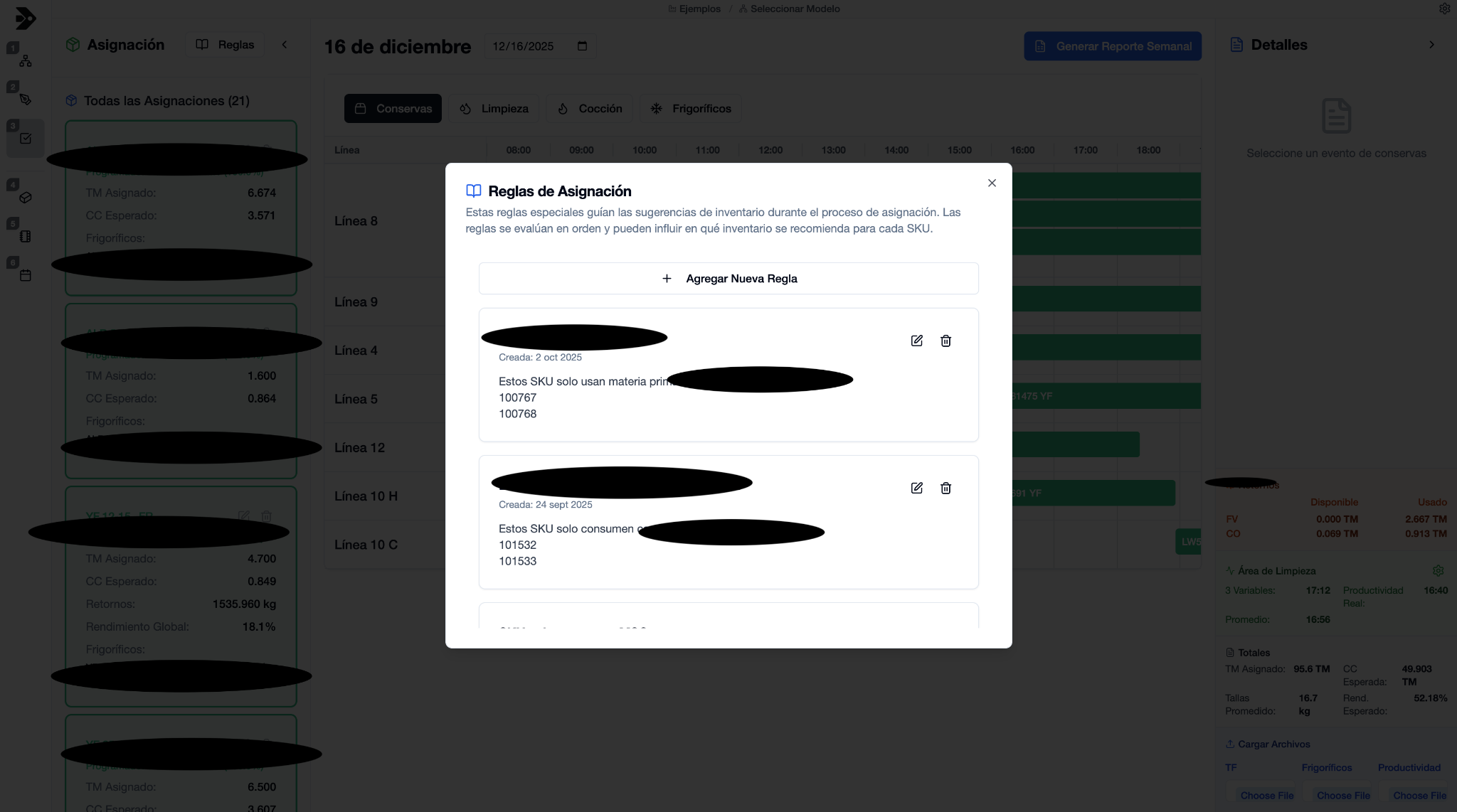

The ProDex planning interface in action. Featured are a Gantt-based schedule, detailed orders and assignments, and a custom rules editor, all configurable by our agent.

Early Signals of Success

Aligning daily release quantities with downstream feasibility produced other promising results. Based on 12 weeks of operational data from September through December of 2025, early results are promising:

With less than 1% of new labor, the amount of clean meat increased by 10%. With a faster planning process and fewer errors, planners were able to squeeze more production out of its tuna cleaning process. A more deliberately planned process is a more efficient one.

Why This Decision Mattered

ProDex's APS did not eliminate human judgment. It removed the friction around it.

Alimentos Prosalud now starts each production cycle with a release plan that is consistent, constraint-aware, and grounded in downstream feasibility. That foundation makes the next step possible: end-to-end factory simulation across sterilization, canning, manual processes, and labeling without having to recalculate its raw material inputs every morning.

The highest-leverage software in a factory lives where decisions are fast-paced and irreversible.

For Alimentos Prosalud, that decision was how much tuna to release each day. And reducing that decision from a day of spreadsheet work down to a few minutes of structured judgment changed everything.

In the first half of 2026, ProDex and Alimentos Prosalud will build on this foundation, expanding the model downstream into larger systems within the factory and incorporating end-to-end simulation. We look forward to continuing our strong partnership with Alimentos Prosalud as ProDex grows into the all-in-one factory tool for operational decision-making.