Production Excellence.

Mathematically Guaranteed.

AI that respects the math. Plans You Can Trust.

Model your factory. Optimize your layout. Schedule every job. ProDex handles the full loop, from floor design to daily dispatch, and returns plans that satisfy every constraint, every time.

DoD Tradewinds Certified · Trusted by U.S. Defense Manufacturers

Many Uses.

From daily scheduling to long-term optimization, ProDex helps factories make clear, optimal decisions.

Automatically generate and adapt production plans that balance materials, labor, and capacity. Rush orders, machine changes, and material delays are absorbed and re-optimized in seconds.

Analyze bottlenecks and simulate resource shifts to maximize utilization and output. See exactly where time is lost and what to change.

Understand OEE, WIP, and order completion. Forecast risk and understand the tradeoffs behind every operational decision before committing.

Reactive planning

The plan updates itself when things change

Fragmented data

Every order, resource, and constraint in one view

Changeovers eat hours

Jobs sequenced automatically to cut changeover time

No forward visibility

Simulate tomorrow's plan before the shift starts

Promising delivery without knowing feasibility

Run a feasibility check before you commit

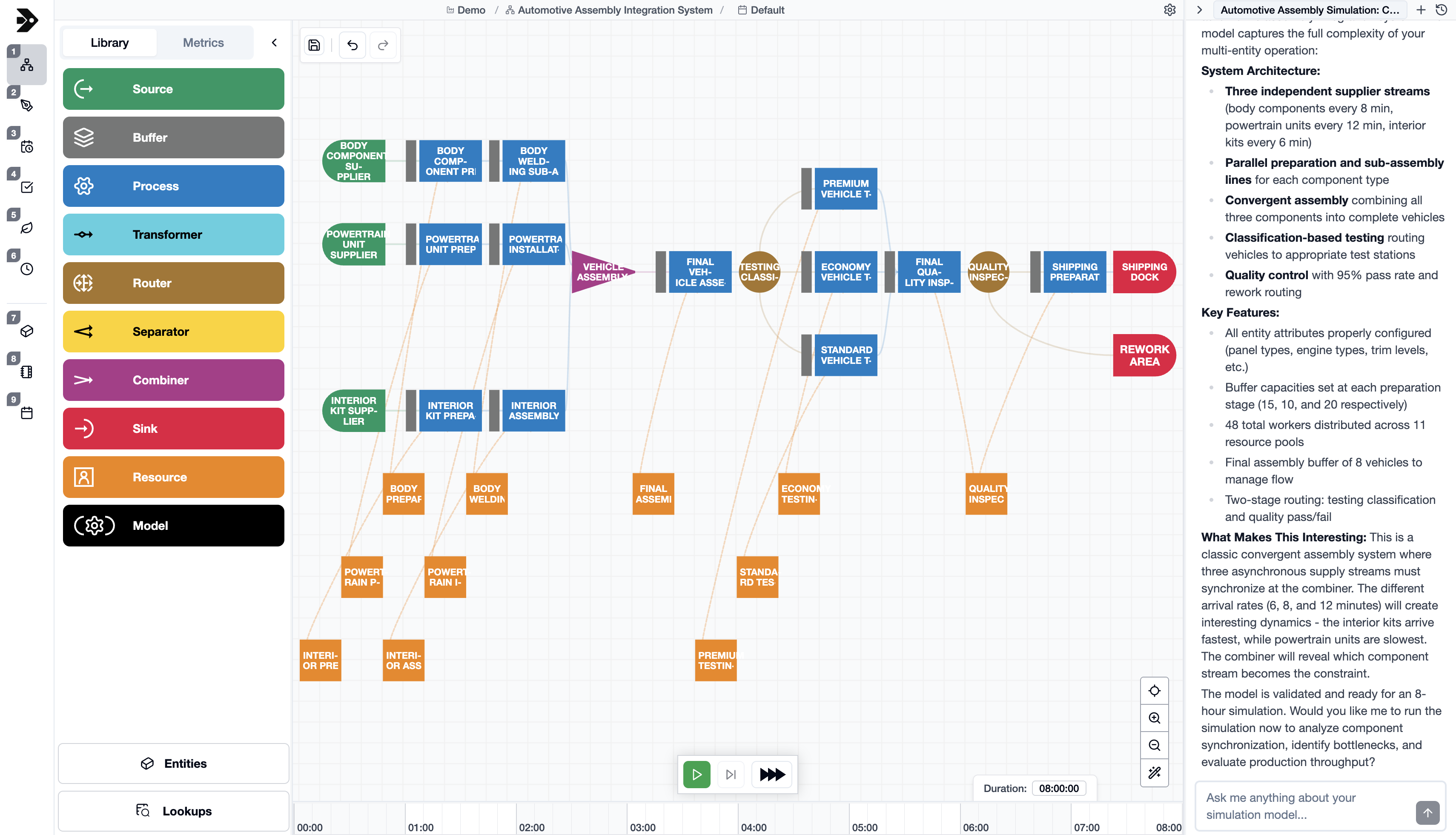

Conversational AI makes simulation creation 100x faster and accessible for all technical levels. What used to take hours or days now takes seconds to minutes.

- Real-time constraint optimization

- Multi-resource scheduling

- Demand forecasting integration

- Automated order routing

Turn scenarios and production plans into actual schedules within the simulation. Identify bottlenecks and find solutions in real-time with agentic analysis.

- Real-time simulation engine

- Scenario comparison tools

- Performance impact analysis

- Risk assessment modeling

Run unlimited what-if scenarios to understand the impact of changes before committing resources. Compare alternatives and make confident decisions backed by simulation data.

- Parallel scenario comparison

- Change impact visualization

- Resource allocation testing

- Constraint sensitivity analysis

The foundation powering every module above.

Harnesses the power of AI throughout the entire platform for intelligent decision-making

4-10 week deployments. We beat competitors by months, getting you to value faster

ROI in under 3 months with rapid deployment and continued support

Serving defense primes and manufacturers, commercial customers, and the DoD

A 4-10 week initial white-gloving and pilot period with our dedicated engineers ensures a 100% success rate within our customers to-date.

Yes, our platform can be tuned for specific manufacturing sectors such as food & beverage, aerospace & defense, CPG, electronics, etc.

ProDex is designed to work alongside existing data systems with hearty integrations.

Our platform adapts easily to the shifting landscapes of factories via our AI-intelligence layer.

Yes, we provide end-to-end white glove implementation and ongoing customer success management to ensure you get maximum value from the platform.

Transform your factory from reactive firefighting to proactive intelligence.

Assessed “Awardable” in CDAO’s Tradewinds Solutions Marketplace

Assessed “Awardable” in CDAO’s Tradewinds Solutions Marketplace

.png)